At present, there are more than 70 cannabinoids isolated from cannabis plants, of which CBD (cannabidiol) and THC (tetrahydrocannabinol) have the highest content and are isomers of each other. The significant difference between CBD and THC is that THC is hallucinogenic and addictive, while CBD is not hallucinogenic and addictive. It also has inhibitory effects on this “toxicity”. It is effective in analgesia, sleep aid, anti-inflammatory, Anti-oxidation, neuroprotection, anti-anxiety, anti-tumor, liver protection, anti-diabetic and other aspects have outstanding effects.

As the efficacy of CBD has been widely studied, its downstream applications have become increasingly abundant. CBD can be used as skin care products, with anti-oxidation, anti-inflammatory, acne and acne removal effects; CBD can be used as medical treatment, has mature products in the treatment of epilepsy and multiple sclerosis (MS)-British GW company has developed Sativex and Epidiolex medicines with CBD as the main ingredient are released; CBD can be used in foods and has the effects of calming and improving sleep quality. So, how is CBD obtained from hemp plants? In addition to directly derived from plants, are there other ways to get CBD?

1.Extraction method for CBD

In general, you can get CBD from the following cannabis plants:

- Industrial hemp (HEMP), also known as hemp and hemp, shows no psychoactivity with THC content < 0.3%.

- Recreational cannabis, or marijuana, where THC content is > 0.5%, produces strong psychoactive and addictive characteristics;

- The content of THC in medical marijuana is between 0.3% and 0.5%, which has a medicinal tendency.

A prerequisite for extracting CBD from cannabis plants is to reduce THC content as much as possible. Therefore, THC content must be controlled from the source, that is, select hemp plants with as little THC content as possible and as much CBD content as possible, that is, industrial hemp. So, how to extract CBD from industrial hemp? At present, the common methods include solvent extraction, supercritical CO2 extraction and olive oil extraction.

(1). Solvent extraction method

CBD can be obtained from industrial hemp by solvent extraction, which is a relatively mature method in industry. Its basic principle is to extract phenolic substances from plants by soaking in ethanol and stirring or spraying the pre-treated plant raw materials.

Solvent extraction method for CBD

- Pretreatment of hemp plants: grinding, heating to remove water to increase the contact effect between plants and ethanol, enzyme treatment to break covalent bonds, etc.

- Extraction: Add the liquid ethanol into the cannabis plant raw material and mix it for a few minutes to transfer the cannabinoids into the ethanol.

- Concentration: The ethanol is separated from the material residue and then the ethanol/extraction mixture is slowly heated to evaporate the ethanol, leaving only the concentrated plant extract.

Advantages: Economy, simplicity.

Disadvantages: The Hemp Oil finally extracted is a mixture, and some impurities may remain to affect the taste and taste of the product. For example, the residue of chlorophyll will make the finished oil green and bitter. The extraction process is dangerous and ethanol burns easily.

(2). Supercritical CO2 extraction method

CO2 changes with pressure and temperature and becomes a gas, liquid or solid. Supercritical CO2 is a substance in the intermediate state between gas and liquid. On the one hand, it has the properties of liquid fluidity and the ability to extract some fat-soluble substances. On the other hand, it has good diffusivity, similar to gas.

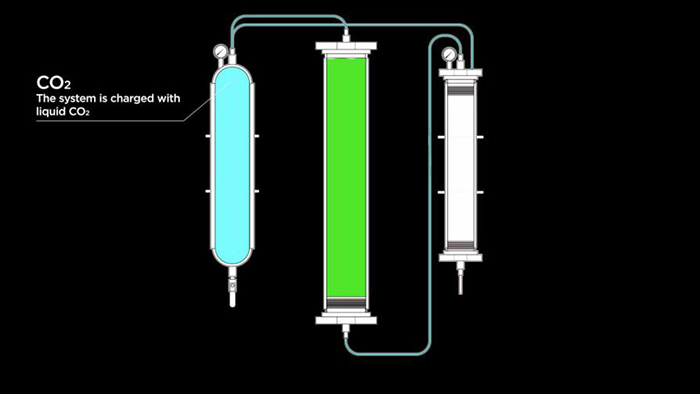

Supercritical CO2 extraction technology is a new material extraction technology developed by using supercritical fluid. This method of extraction usually requires the use of a special “closed loop extractor” with three chambers.

Supercritical CO2 extraction method for CBD

- When extractionSupercritical CO2 extraction method for CBD is carried out, solid CO2 (dry ice) from the first chamber is pumped into the second chamber, where it comes into contact with the industrial hemp material in the second chamber.

- The second chamber maintains a specific temperature and pressure, allowing the CO2 to behave more like a liquid (supercritical CO2). In this case, CO2 can act like a liquid solvent by passing through the plant material and extracting the cannabinoids needed from it.

- The CO2/ cannabinoid mixture is pumped into the third chamber, which has lower pressure and higher temperature, causing THE CO2 gas to rise to the top of the chamber, while the cannabinoid and other extracts fall to the bottom of the chamber for collection.

Advantages: CO2 is safe, non-toxic, not easy to burn, easy to separate after extraction; CO2 is an inert gas, which is not easy to react with cannabinol and other substances. The extracted material is pure, without chlorophyll and has little risk of pollution.

Cons: Expensive equipment (starting at $39,000), complex operation.

(3). Olive oil extraction method

Olive oil extraction is a simple method for making CBD products at home.

- Industrial hemp plants are heated to a certain temperature and held for a period of time to activate the chemicals in them.

- Add plant materials into olive oil, heat to 100℃ and keep for 1-2 hours to extract cannabinoids and obtain CBD oil.

Olive oil extraction method for CBD

Advantages: simple, safe and economical

Disadvantages: Olive oil is perishable, so it must be stored in a cool, dark place and used as soon as possible; The capacity is too low to be suitable for mass production.

The extraction efficiency of the above three CBD extraction methods all depends on the amount of CBD in the original industrial hemp. By cultivating transgenic hemp plants, plants with higher CBD content can be obtained, thus improving the yield and efficiency of hemp plant extraction at the source.

At present, “Yunma No. 1” and “Yunma No. 7”, two types of industrial hemp mainly cultivated in China, have not yet exceeded 1% in CBD content, and this figure may exceed 2% in the future. At present, the average CONTENT of CBD in global industrial hemp seeds is between 4% and 5%, up to 18%. The increase of CBD content may mean that THC content will also increase, which is also one of the main reasons for our government to consider. It is believed that with the maturity of the technology, the cannabinoid CBD content in cannabis plants will continue to increase for the benefit of mankind.

Trait, which grows genetically modified marijuana crops and uses gm technology to purify the plant, says Ronan Levy, chief strategy officer at Trait, a maker of genetically modified marijuana plants. His company’s top priority is to find a way to induce cannabis plants to produce cannabinoids in every cell of the plant to achieve pure purification and product development.

The extraction technology of industrial hemp has been developed and mature, and the chemical synthesis and biosynthesis of CBD are being widely studied.

2.Chemical synthesis method for CBD

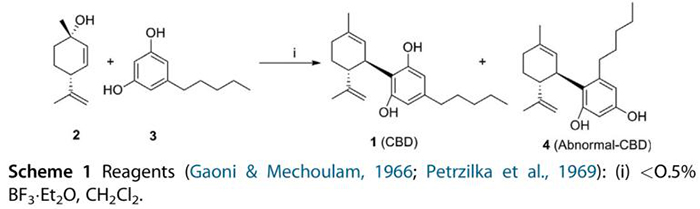

(1). Traditional synthesis methods for CBD

Traditional synthesis methods for CBD

- Catalyst: Boron trifluoride

- Production rate: 41%

- Disadvantages: low yield and many impurities; Complex and costly

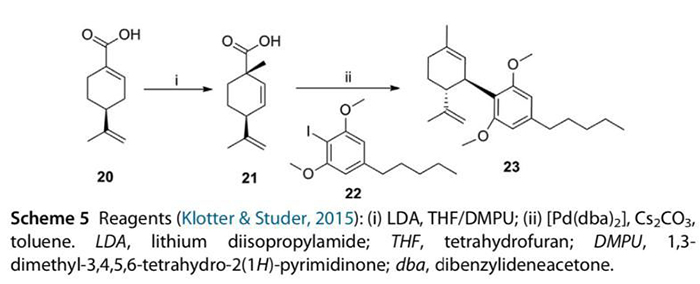

(2). Optimized synthesis method for CBD

Optimized synthesis method for CBD

- Catalyst: palladium

- Production rate: 74%

- Bright spot: change the catalyst to palladium, reduce by-products, high purity, high yield

Due to the complex molecular space configuration of CBD, the yield of traditional synthesis methods of CBD is low (only about 40%), and a large number of by-products will be produced, so there are great limitations in extraction. Although the optimized synthesis method can obtain pure CBD and the yield has been improved to some extent (74%), the new method is still in the laboratory stage at present, and the high requirement of synthesis conditions makes the industrialization cost too high to meet the market requirements.

3.Biosynthesis method for CBD

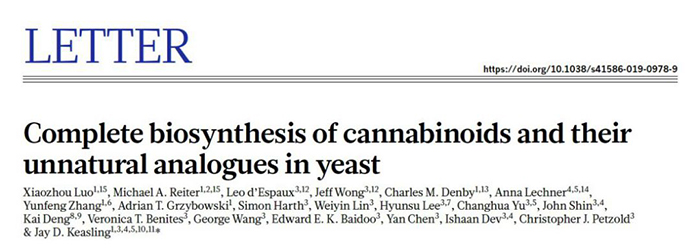

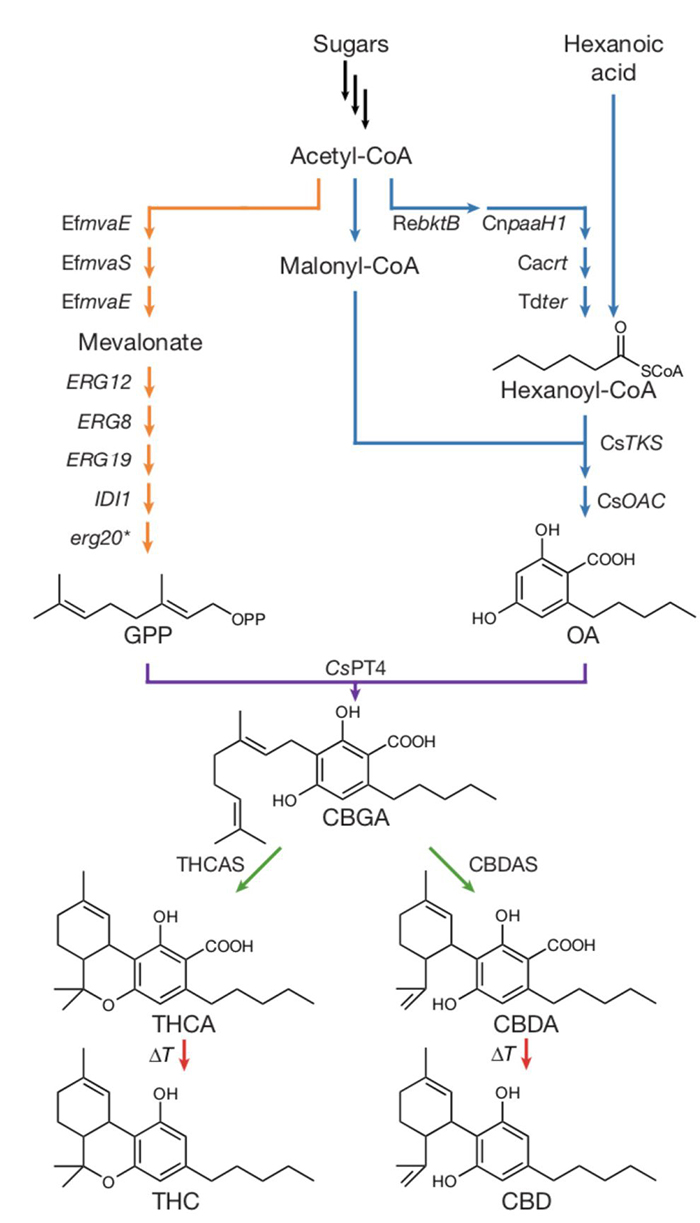

On February 28, 2019, the university of California, Berkeley, Jay Keasling research published in Nature, such as Dr Luo Xiaozhou Complete biosynthesis of cannabinoids and their unnatural analogues in yeast paper expounds the related study of the biosynthesis of CBD, will express CBD related genes in plants into yeast, and the yeast was modified amplification, Thus the biocomplete synthesis of cannabinoids and their non-natural derivatives can be achieved.

Biosynthesis method for CBD

Study to galactose as raw material, own A hydroxyl of s.cerevisiae pentanoic acid pathway (mevalonate pathway), and introduces A synthesis hexanoyl coenzyme A (hexanoyl – CoA) metabolic pathways, through A variety of different species of foreign genes and key enzymes, completed in saccharomyces cerevisiae cannabinoid biosynthetic pathway of heterologous refactoring, implements including marijuana terpene phenolic acids (CBGA), four hydrogen cannabinol (THCA), cannabidiol (CBDA), A variety of main cannabinoid and its derivatives of biological total synthesis. This metabolic pathway is shown in the figure below:

Biosynthesis method

Back in 2017, when Jay Keasling filed a patent for this approach, he worked with the biotechnology startup Demetrix to bring the process from the lab to commercial production, using the technology to produce the rarest cannabinoids at a reasonable price, and bringing the cost of production below $1,000 per kg. Montreal-based Hyasynth also wants a piece of the action after receiving a million-dollar investment from Canadian marijuana distributor OrganiGram to speed up the spread of its own bio-synthetic cannabinoids.

Biosynthesis method for CBD

Biosynthesis is the result of work begun in the 1990s by the Human Genome Project, which creates everything from biofuels to medicine and even clothing fibers by altering the genes of simple microbes such as yeast, bacteria, molds, lichens and fungi. Biosynthesis is considered to be a cheaper way to obtain cannabinoid concentrate, but there are still difficulties:

Yield problem: The current bio-synthetic CBD yield is only 10mg/L, which may need to be expanded 1000 times to achieve industrialization. (at present, the biosynthesis yield of artemisinin under industrial conditions reaches 25g/L).

Technical problems: Engineered bacteria for biosynthesis require modification of dozens of genetic loci, which can be difficult to control, and maintaining strain stability is also a problem.

Conclusion

CBD extraction technology aims to improve the extraction rate and purity of CBD, remove THC residue as far as possible, avoid the use of toxic organic solvents, and ensure the safety and environmental protection of products, and reduce costs as far as possible. In the current CBD acquisition methods, the technically sophisticated extraction method still occupies the mainstream position, while chemical synthesis is faced with many challenges such as high cost and complex process, so the bio-synthesis may be worth exploring.